Now it is true that you can probably buy ready made hazard warning systems on eBay for a similar price to the DIY version, but it just isn't half as much fun!

Here is the list of parts that the Practical Classics system requires:

and also the circuit diagram:

One thing that is certainly different about this version, is that it can be used on anything from 6 volt to 24 volt vehicles thanks to the solid state voltage regulator that pumps out an even 6 volts regardless of the input voltage. This voltage is required to drive the 6 volt relay circuit that is used to switch the battery voltage to the indicators.

Another difference is the inbuilt multi-colour LED that is used to indicate a blown bulb through the use of reed switches. I didn't want this functionality - after all, in our old vehicles we know when a bulb has blown - our indicators stop working !! So I stopped at the output from the relays and connected into the indicators.

One problem with the write up in the magazine is that they left one very important point out, or rather didn't explain it properly. The timing mechanism that controls the flash rate of the hazard warning system is controlled by the BLUE LED - so you need to make sure that you buy a flashing LED. This does limit the amount of control that you have over the flash rate, but I reckon mine is flashing at roughly 2 flashes per second which is the maximum allowed in the regulations.

I copied the diagram out on a piece of squared paper so that I could mimick the copper strips on a piece of strip-board and created my own version of the circuit diagram with markings for where I would need to cut the copper strip, and where to solder on the components.

Here is my completed unit:

So that I could test it out, I found a few indicator units for my Rover P6 and connected it up - here's a video....

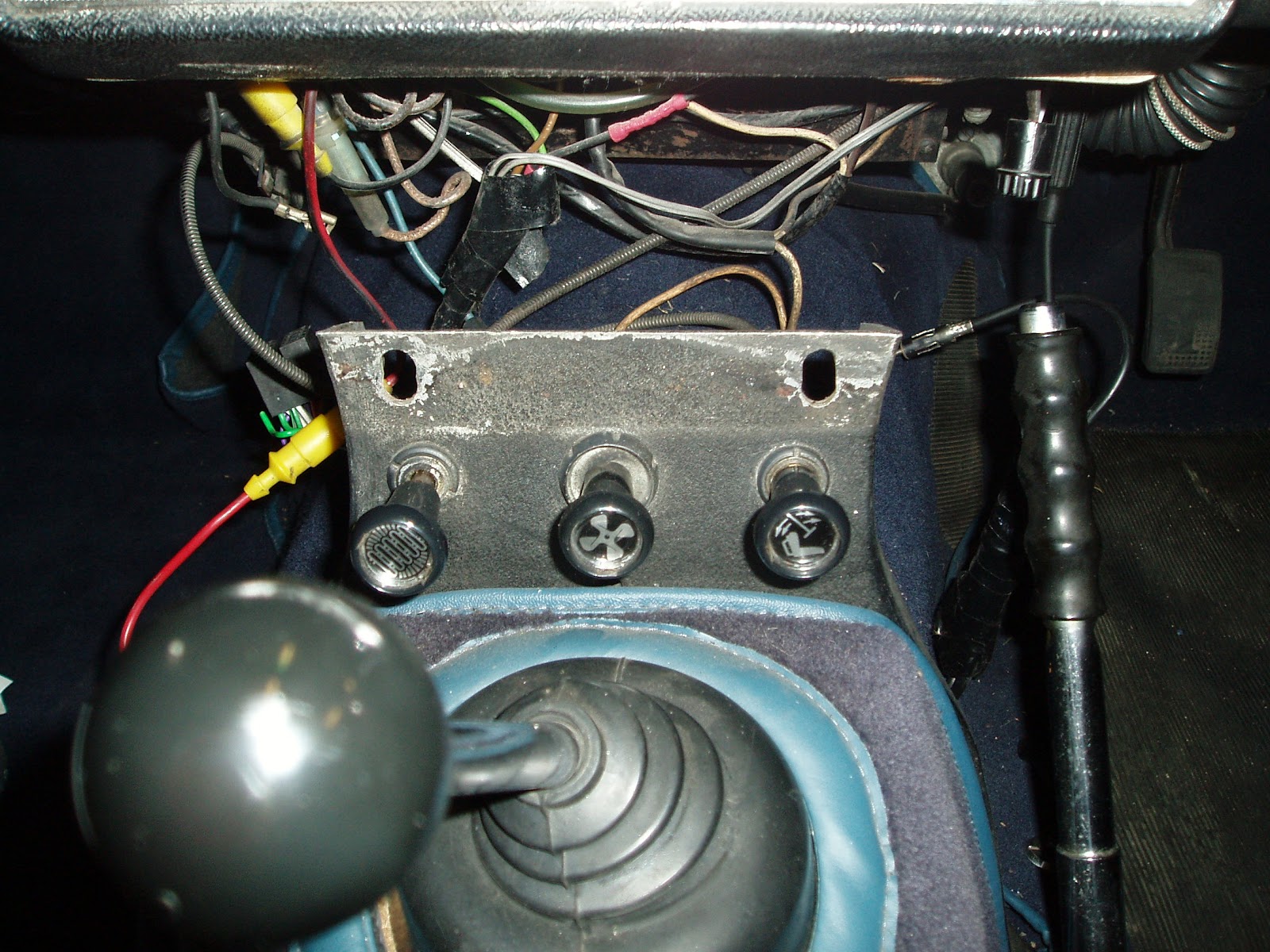

I fitted it under the dashboard fastened to the steering column. I didn't want it to be a permanent fixture. Also, tucked up out of the way, the MOT tester can't see it and therefore never tests for it. I also don't like making permanent holes in the car if there is no need to do so.

Please feel free to comment on my blog by clicking on the "comments" link below.